SERVICE

Dingbo is dedicated to being there for you for the life of your machine.

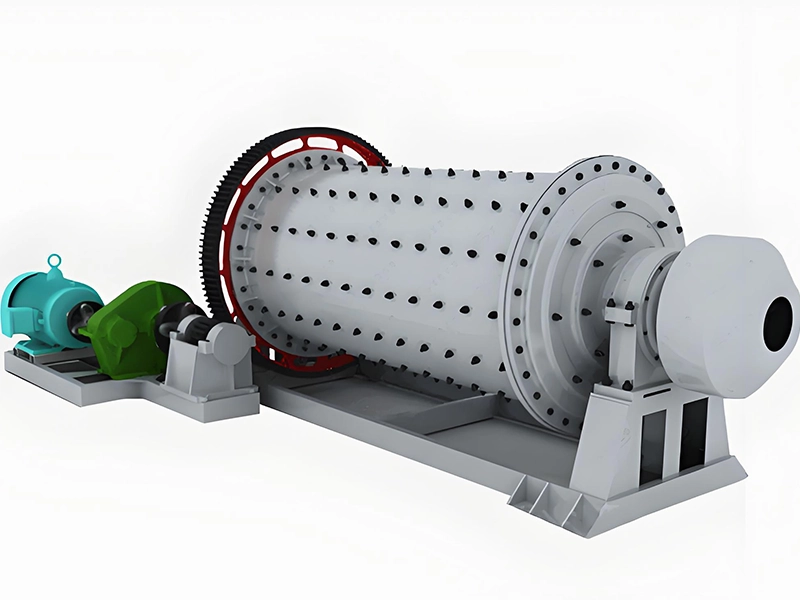

| Product Specifications | Mill Type | Transmission Type | Speed Reducer | Motor Power (kw) | Production Capacity (t/h) | Total Weight (t) | |

| Models | Speed ratio | ||||||

| Φ1.83x7 | Open flow | Edge | ZD60 | 4.5 | 245 | 6.5-8 | 438 |

| Φ2.2x7.5 | Open flow | Edge | ZD70 | 5 | 380 | 8-10 | 64.8 |

| Φ2.2x11 | Open flow | Edge | D110 | 35.5 | 630 | 12-13 | 104.6 |

| Φ2.2x13 | Open flow | Edge | D110 | 35.5 | 630 | 16-18 | 114 |

| Φ2.4x13 | Open flow | Edge | D110 | 35.5 | 800 | 20-23 | 130.6 |

| Φ2.6x13 | Open flow | Edge | MFY100 | 19.5 | 1000 | 28-32 | 158 |

| Φ3x9 | Circular flow | Edge | D125 | 41.2 | 1000 | 28-36.5 | 168 |

| Φ3x11 | Circular flow | Edge | D140 | 42.8 | 1250 | 36-47 | 180 |

| Φ3.2x13 | Open flow | Edge | D140 | 36.5 | 1600 | 45-50 | 225 |

| Φ3.5x13 | Circular flow | Edge | JDX1000 | 5.84 | 2000 | 60-65 | 275 |

| Φ3.8x13 | Open flow | Core | MFY250 | 16.5 | 2500 | 60-62 | 320 |

| Φ4.2x13 | Open flow | Core | JQS3550 | 15.6 | 3530 | 85-87 | 380 |

| Φ4.6x14 | Circular flow | Core | JSI160-C | 14.6 | 4200 | 120-135 | 485 |