Overview

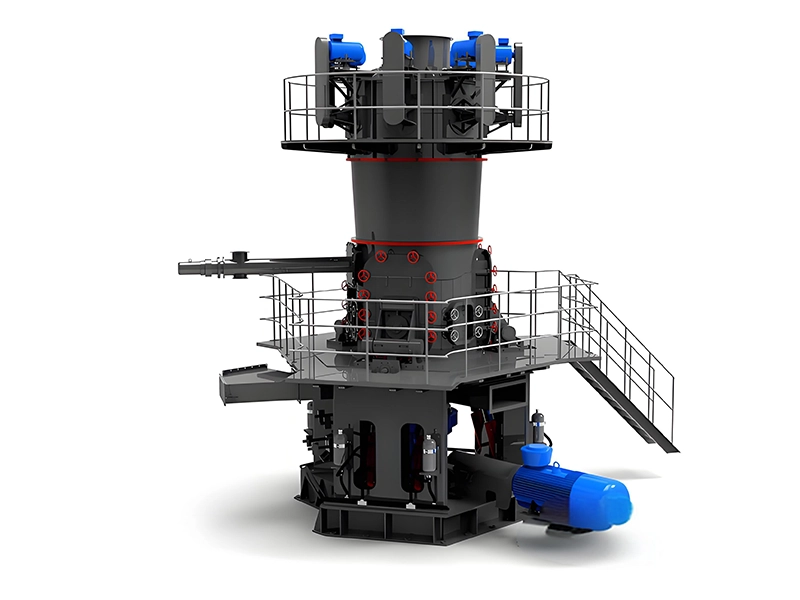

Dingbo vertical mills feature a rational and reliable structure as well as an advanced process that combines drying, grinding, separation and conveying, which is suitable for grinding materials of different types and sizes.

|

Model

|

Yield (t/h)

|

Grinding Plate Diameter (mm)

|

Grinding Path Diameter (mm)

|

Material Moisture (%)

|

Raw Material Fineness (%)

|

Raw Material Moisture (%)

|

Main Motor Power (kW)

|

|

DBGM1300

|

20-25

|

1870

|

1300

|

<10%

|

R0.08≤12%

|

≤1%

|

200

|

|

DBGM1500

|

26-34

|

2180

|

1500

|

<10%

|

R0.08≤12%

|

≤1%

|

280

|

|

DBGM1700

|

40-50

|

2400

|

1700

|

<10%

|

R0.08<12%

|

≤1%

|

400

|

|

DBGM1900

|

60-70

|

2680

|

1900

|

<10%

|

R0.08<12%

|

≤1%

|

500

|

|

DBGM2200

|

85-110

|

2900

|

2200

|

<10%

|

R0.08<14%

|

≤1%

|

800

|

|

DBGM2400

|

95-130

|

3140

|

2400

|

<10%

|

R0.08<14%

|

≤1%

|

900

|

|

DBGM2800

|

120-160

|

3300

|

2800

|

<10%

|

R0.08<14%

|

≤1%

|

1250

|

|

DBGM3400

|

190-240

|

4560

|

3400

|

<10%

|

R0.08<15%

|

≤1%

|

1800

|

Vertical coal mills are used for grinding bituminous coal, anthracite and petcoke for the burning systems in clinker burning and power generation according to the type and quantity of additives.

Note: Raw coal size 40~50mm, feed moisture ≤15%, final product moisture ≤1.0%, final product finenessR80μm=10%~12% (bituminous coal), R80μm=1%~3%(anthracite), coal grindability HGI=40~70.

|

Model

|

Capacity (t/h)

|

Grinding Plate Diameter (mm)

|

Grinding Path Diameter (mm)

|

Maximum Feed Size (mm)

|

Raw Coal Moisture (%)

|

Coal Powder Fineness (%.R0.08)

|

Coal Powder Moisture (%)

|

Main Motor Power (kW)

|

|

DBGM800M

|

5-8

|

1100

|

800

|

25

|

<10

|

5-12%

|

≤1%

|

110

|

|

DBGM1100M

|

7-12

|

1520

|

1100

|

25

|

<10

|

5-12%

|

≤1%

|

132

|

|

DBGM1300M

|

10-15

|

1870

|

1300

|

25

|

<10

|

5-12%

|

≤1%

|

185

|

|

DBGM1500M

|

16-22

|

2180

|

1500

|

30

|

<10

|

5-12%

|

≤1%

|

250

|

|

DBGM1700M

|

20-28

|

2400

|

1700

|

30

|

<10

|

5-12%

|

≤1%

|

315

|

|

DBGM1900M

|

26-35

|

2680

|

1900

|

35

|

<10

|

5-12%

|

≤1%

|

400

|

|

DBGM2200M

|

40-45

|

2900

|

2200

|

40

|

<10

|

5-12%

|

≤1%

|

500

|

A vertical slag mill is used for grinding and drying water quenched slag that is generated by blast furnaces into an active material which is then added to the finished cement.

Note: Feed moisture <20%, feed size <10mm, final product moisture≤0.5%, final product fineness <4200cm2/g~5000cm2/g, power consumption <33 kWh/t.

|

Model

|

Capacity (t/h)

|

Annual Output (Ten Thousand Tons/Year)

|

Grinding Plate Diameter (mm)

|

Grinding Path Diameter (mm)

|

Maximum Feed Size (mm)

|

Slag Moisture (%)

|

Product Specific Surface Area (m²/kg)

|

Product Moisture (%)

|

Main Motor Power (kW)

|

|

DBGM1500S

|

6-8

|

5

|

2180

|

1500

|

<50

|

<12

|

≥420

|

<1

|

280

|

|

DBGM1700S

|

10-12

|

8

|

2400

|

1700

|

<50

|

<12

|

≥420

|

<1

|

400

|

|

DBGM1900S

|

15-18

|

10

|

2680

|

1900

|

<50

|

<12

|

≥420

|

<1

|

500

|

|

DBGM2200S

|

25-28

|

15

|

2900

|

2200

|

<50

|

<12

|

≥420

|

<1

|

800

|

|

DBGM2400S

|

35-40

|

20

|

3140

|

2400

|

<50

|

<12

|

≥420

|

<1

|

1250

|

|

DBGM2800S

|

45-50

|

30-35

|

3300

|

2800

|

<50

|

<12

|

≥420

|

<1

|

1600

|

A vertical cement mill is used for the finish-grinding of cement.

Its grinding table liners and roller sleeves are made from wear-resistant hard facing material or ceramic material. Blades of the separator use high-quality and wear-resistant plates. Thus equipment wear can be minimized, reducing maintenance time and thus increasing availability and overall performance.

The separator combines highly efficient dynamic and static cages, which ensures that the specific surface area of cement can be adjusted for the finished cement product to obtain the required particle size distribution

Note: Max. feed size 50~80mm, final product fineness 3300~3800cm2/g, R80μm≤1%, R45μm≤8%. Output is subject to change according to the type and quantity of additives

A vertical raw mill is mainly used in cement plants for raw material grinding.

Simple process flow, providing for drying, grinding and classifying all in one equipment

Minimum floor space requirement, compact layout and low investment in civil works

High grinding efficiency, low energy consumption and low wear on metal parts

Each roller is operated independently in compressing and grinding materials. Thus taking a vertical mill with 4 rollers as an example: when two rollers are retracted, the remaining two in operation can still reach 70% of the rated output.

The separator combines highly efficient dynamic and static cages, which provides for high precision in raw meal fineness control and sensitive adjustment of the cut-off point.

Vertical limestone mills (or: vertical mills for desulfurization) are used for grinding limestone into powder which will then be used in the desulfurization process in power plants or in the reduction process in metallurgical plants.

Note: Limestone feed moisture ≤3%, final product moisture ≤0.5%, final product fineness R45μm=5%~20%

Efficient and energy-saving: The vertical grinding machine adopts advanced grinding technology, which can achieve high efficiency grinding at lower energy consumption, thereby reducing production costs.

High yield: The design of vertical grinding machines can provide high yield and meet the needs of large-scale production.

Fineness control: By adjusting the grinding disc speed and material feeding speed, the fineness of the powder can be precisely controlled to meet the needs of different applications.

High degree of automation: Modern vertical grinding machines are usually equipped with advanced automation control systems, which can achieve remote monitoring and automated operation.

Low noise and low dust: The equipment adopts a closed design, which reduces the generation of noise and dust and meets environmental requirements.

Easy maintenance: The structural design of the vertical grinding machine is reasonable, easy to maintain and operate, and reduces maintenance costs.

Strong durability: Made of high-strength materials, ensuring the long-term stable operation of the equipment.

Strong adaptability: able to handle various materials, such as cement, ore, chemical raw materials, etc.

Small footprint: The compact design of the vertical grinding machine reduces footprint and is suitable for use in factories with limited space.

High return on investment: Efficient production capacity and lower operating costs result in a higher return on investment.

The advantages and advantages of vertical grinding machines have made them widely used in industries such as cement, chemical, and building materials.

Material conveying: Materials are fed into the interior of the mill through the feeding system.

Grinding disc: The material is fed into the inside of the grinding disc, which is equipped with multiple grinding rollers. The grinding rollers rotate to grind the material. At the same time, the grinding disc is equipped with a grinding ring, which, together with the grinding roller, grinds the material.

Grading and screening: The ground material is sent to the grading system, which screens the material and sends the coarse-grained material back to the grinding disc for further grinding, while the fine-grained material is screened out.

Collection and packaging: The filtered fine particle materials are collected through a collection system and packaged through a packaging system to meet the different needs of users.

The vertical grinding machine achieves ultrafine grinding of materials through the rotation of the grinding disc and the grinding effect of the grinding ring and the grinding roller. At the same time, the equipment adopts a closed design, reducing the generation of noise and dust, which meets environmental protection requirements.