SERVICE

Dingbo is dedicated to being there for you for the life of your machine.

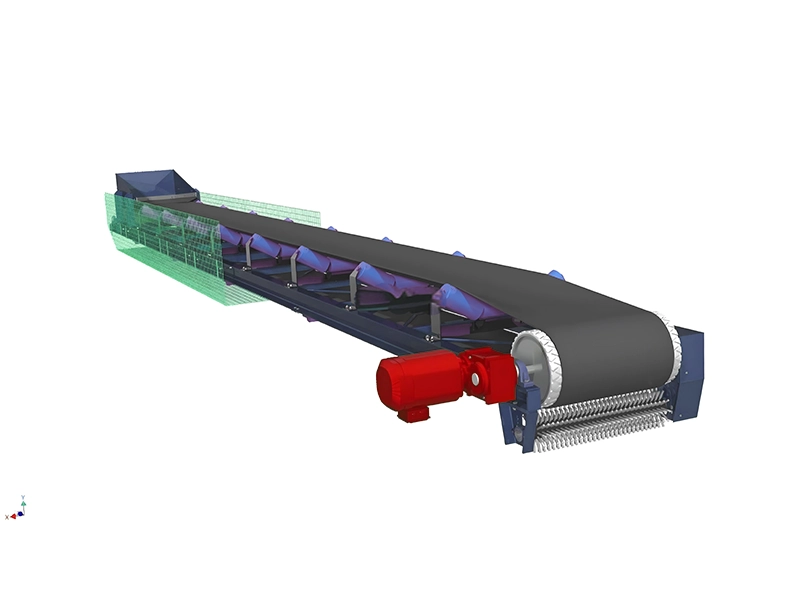

| Model | Belt Width(mm) | Nominal Power(kw) | Conveyor Speed(m/s) | Capacity (t/h) |

| B400 | 400 | <12m=2.2 | 0.8-2.0 | 40-80 |

| 12m-19m=3 | ||||

| 20m-25m=4 | ||||

| B500 | 500 | <12m=4 | 0.8-2.0 | 78-191 |

| 12m-19m=5.5 | ||||

| 20m-30m=7.5 | ||||

| B650 | 650 | <12m=4 | 0.8-2.0 | 131-323 |

| 12m-19m=5.5 | ||||

| 20m-30m=7.5 | ||||

| B800 | 800 | <10m=5.5 | 1.0-2.0 | 278-546 |

| 10m-15m=7.5 | ||||

| 16m-20m=11 | ||||

| 21m-25m=15 | ||||

| 26m-30m=18.5 | ||||

| B1000 | 1000 | <10m7.7 | 1.0-2.0 | 435-853 |

| 10m-15m=11 | ||||

| 16m-23m=15 | ||||

| 24m-30m=22 | ||||

| B1200 | 1200 | <10m=11 | 1.0-2.0 | 650-1020 |

| 10m-17m=15 | ||||

| 18m-22m=18.5 | ||||

| 23m-26m=22 | ||||

| 27m-30m=30 | ||||

| B1400 | 1400 | / | 1.2-2 | 760-1400 |