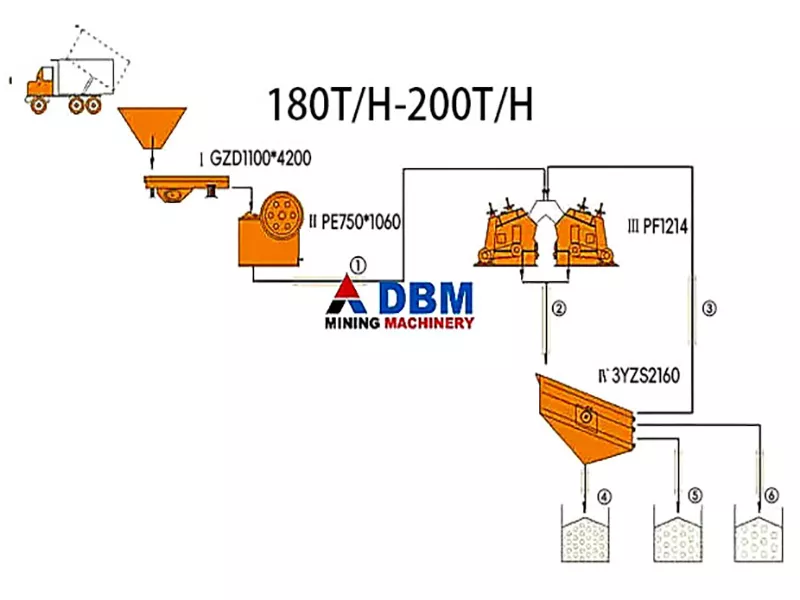

| NO. | equipment | model | qty. |

| Ⅰ | Vibrating Feeder | GZD1100*4200 | 1 |

| Ⅱ | Jaw Crusher | PE750*1060 | 1 |

| Ⅲ | Impact Crusher | PF1214 | 2 |

| Ⅳ | Vibrating Screen | 3YK2460 | 1 |

| ① | Belt Conveyor | B1000*20M | 1 |

| ② | Belt Conveyor | B1000*(8+24)M | 1 |

| ③ | Belt Conveyor | B650*25M | 1 |

| ④ | Belt Conveyor | B650*20M | 1 |

| ⑤ | Belt Conveyor | B650*20M | 1 |

| ⑥ | Belt Conveyor | B650*20M | 1 |