SERVICE

Dingbo is dedicated to being there for you for the life of your machine.

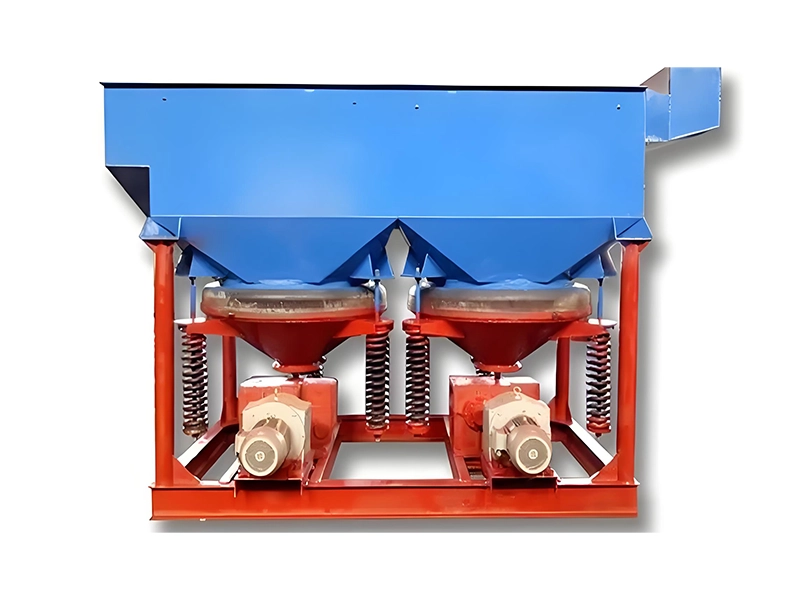

| Model | Stroke coefficient | Stroke(mm) | Jig frequency(order/min) | Feeding particle size(mm) | Processing capacity(T/h) | Water consumption(T/h) | Power(KW) |

| JT1070/2 | 0.5 | 0-12 | 0-170 | 8 | 6-8 | 5-40 | 2.2 |

| JT1515/2 | 0.47 | 0-25 | 0-150 | 10 | 20-35 | 30-120 | 4*2 |

| JT2020/2 | 0.4 | 0-20 | 0-130 | 10 | 40-60 | 60-180 | 5.5*2 |