SERVICE

Dingbo is dedicated to being there for you for the life of your machine.

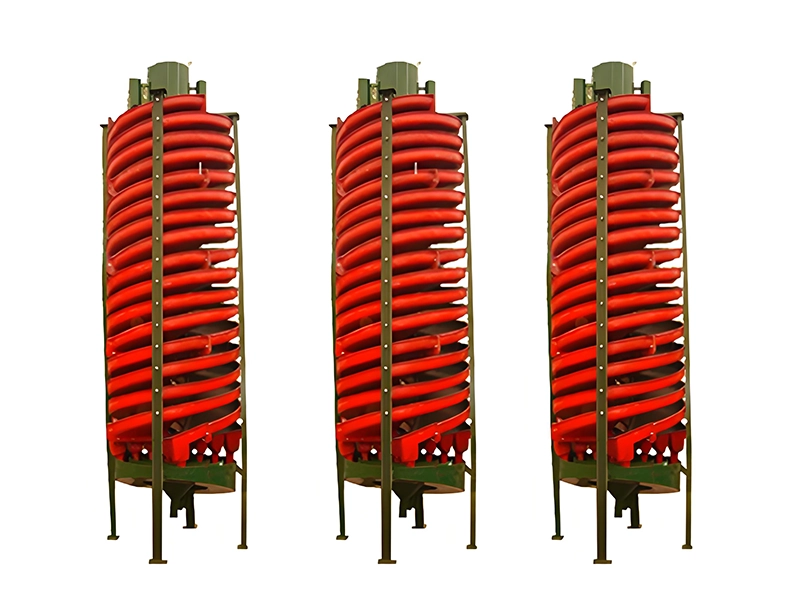

| Model | 5LL-2000 | 5LL-1500 | 5LL-1200 | 5LL-900 | 5LL-600 | 5LL-400 | |

| Spiral Diamter(mm) | 2000 | 1500 | 1200 | 900 | 600 | 400 | |

| Spiral Pitch(mm) | 1200 | 720/540 | 900/720/540 | 675/540/405 | 450/360/270 | 240/180 | |

| Starts | 3 | 4 | 4 | 4 | 2 | 2 | |

| Feeding Size(mm) | 4-0.04 | 0.8-0.037 | 0.3-0.03 | 0.3-0.03 | 0.2-0.02 | 0.2-0.02 | |

| Feeding Density(%) | 20-45 | 30-60 | 25-35 | 25-55 | 25-55 | 25-55 | |

| Capacity(t/h) | 15-40 | 6-8 | 4-6 | 2-3 | 0.4-0.8 | 0.15-0.2 | |

| Dimension(mm) | Length(mm) | 2300 | 1560 | 1360 | 1060 | 700 | 460 |

| Width(mm) | 2300 | 1560 | 1360 | 1060 | 700 | 460 | |

| Height(mm) | 6500 | 5230 | 5230 | 4000 | 2600 | 1500 | |

| Weight(kg) | 1100 | 800 | 600 | 400 | 150 | 50 | |