| Model | Capacity (t/h) | Max. Feeding Sizes (mm) | speed (r/min) | Motor Power (kw) | Overall Dimension (mm) | power supply |

Vibration sensor

Detection range

|

||

| Scattering and central feeding | Full center feeding | Soft material | Hard material | ||||||

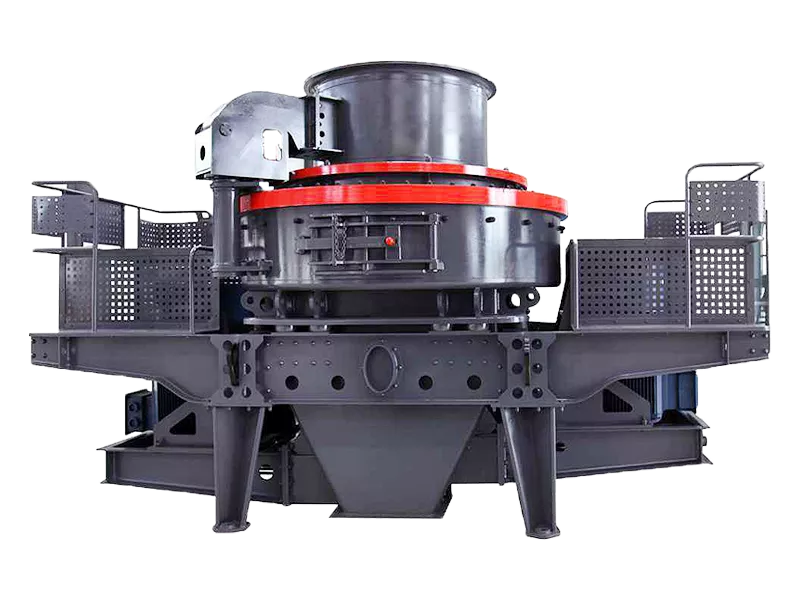

| VSI-7611 | 120-180 | 60-90 | <35 | <30 | 1700-1890 | 4-55×2 | 3700×2150×2100 | 380V:50Hz |

0.1-20 mm/s

Continuing Adjust

|

| VSI-8522 | 240-380 | 120-200 | <40 | <35 | 1530-1700 | 4-110×2 | 4140×2280×2425 | 380V:50Hz |

0.1-20 mm/s

Continuing Adjust

|

| VSI-9532 | 350-540 | 180-280 | <45 | <40 | 1380-1500 | 4-160×2 | 4560×2447×2778 | 380V:50Hz |

0.1-20 mm/s

Continuing Adjust

|

| VSI-1140 | 450-520 | 225-260 | <50 | <45 | 1180-1310 | 4-200×2 | 5000×2700×3300 | 380V/50Hz |

0.1-20 mm/s

Continuing Adjust

|

| VSI-1145 | 500-640 | 250-360 | <50 | <45 | 1100-1310 | 4-220×2 | 5000×2790×3320 | 380V:50Hz |

0.1-20 mm/s

Continuing Adjust

|

| VSI-1263 | 700-850 | 280-480 | <60 | <50 | 900-1200 | 4-315×2 | 5700×2980×4190 | 380V:50Hz |

0.1-20 mm/s

Continuing Adjust

|