mining, building materials, transportation, energy, and chemical industries.

| Model | Screen Size | Number of Screen Layers | Capacity (t/h) | Amplitude | Motor Power (kw) | Vibration Direction Angle (°) | Overall Dimensions (m) |

|---|---|---|---|---|---|---|---|

| ZSF1020 | 1×2 | 1-6 | ≤5-7 | 6-8 | 0.75×2 | 45-60 | 1.3×2.3×1.3 |

| ZSF1030 | 1×3 | 1-6 | ≤5-10 | 6-8 | 0.75×2 | 45-60 | 1.3×2.3×1.3 |

| ZSF1224 | 1.2×2.4 | 1-6 | ≤10 | 6-8 | 1.1×2 | 45-60 | 1.5×2.7×1.6 |

| ZSF1237 | 1.2×3.7 | 1-6 | ≤15 | 6-8 | 1.5×2 | 45-60 | 1.5×2.7×1.6 |

| ZSF1530 | 1.5×3 | 1-6 | ≤20 | 6-8 | 1.5×2 | 45-60 | 1.2×2.3×1.7 |

| ZSF1538 | 1.5×3.8 | 1-6 | ≤25 | 6-8 | 2.2×2 | 45-60 | 1.2×2.3×1.8 |

| ZSF1545 | 1.5×4.5 | 1-6 | ≤30 | 6-8 | 2.2×2 | 45-60 | 1.2×2.3×1.8 |

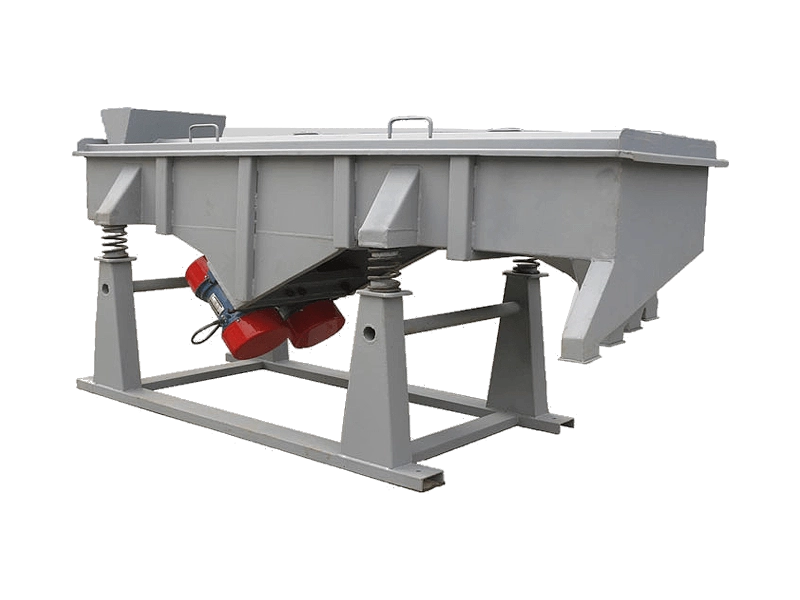

High-frequency vibration

The linear high-frequency screen utilizes high-frequency vibration forces to conduct screening quickly and effectively, enhancing screening efficiency.

Durability

The structure of the linear high-frequency screen is robust and durable, made with wear-resistant and corrosion-resistant materials, suitable for stable operation under long hours and harsh working conditions.