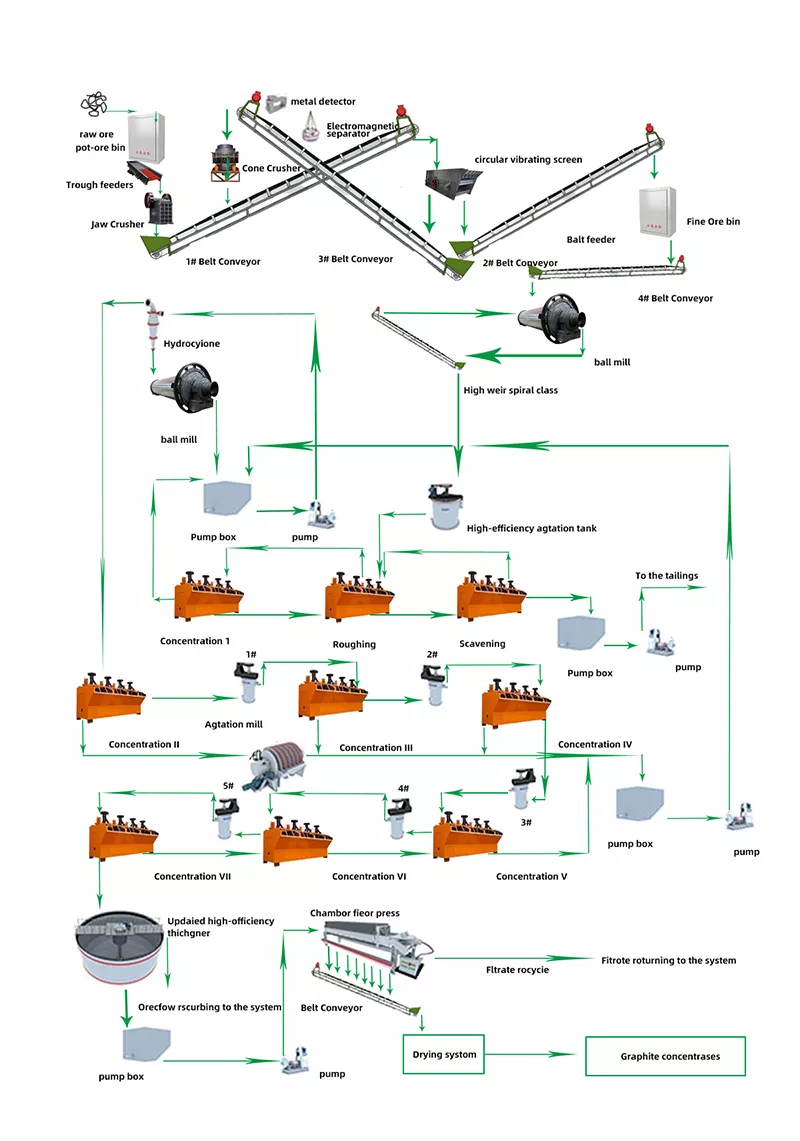

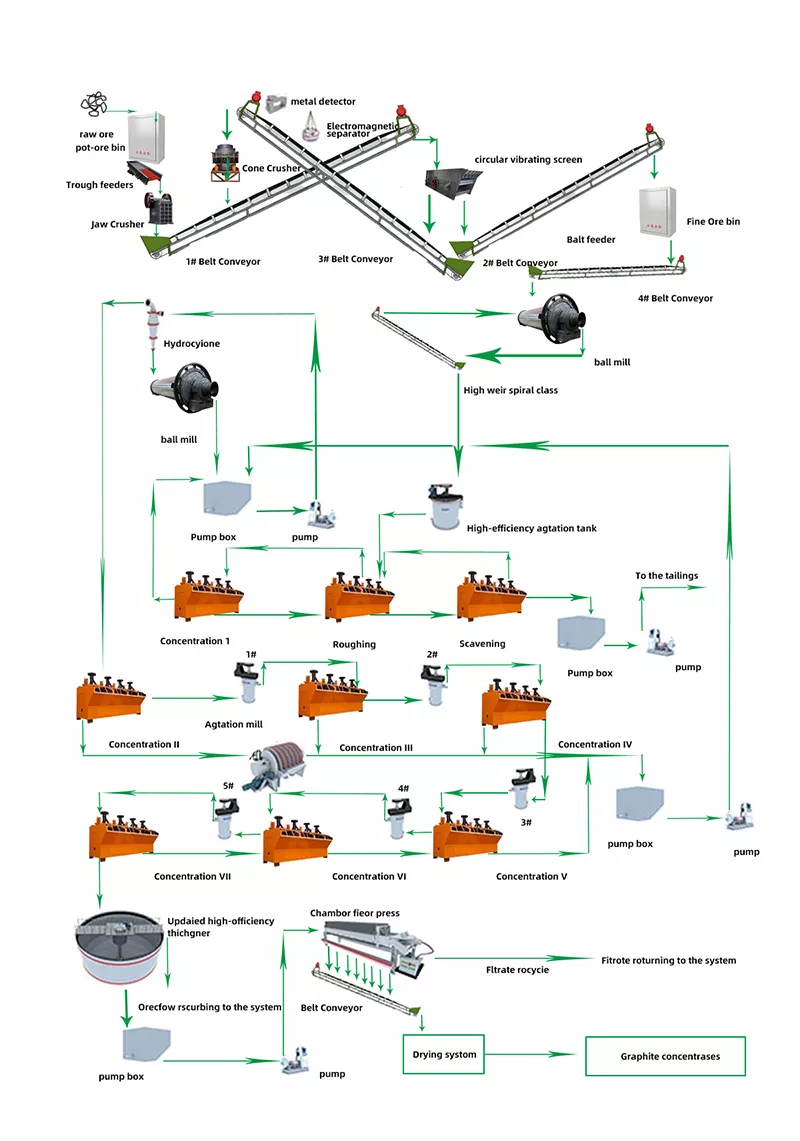

Flow chart of graphite processing plant

The graphite mining processes are mainly the gravity separation process, froth flotation process, electric separation process, and the combination process. And froth flotation process is the main graphite ore processing method. Generally, 90%-97% grade of graphite concentrate can be obtained after the graphite flotation process. For the different graphite ore properties, the graphite mining processes are also different.

Multi-stage Grinding and Multi-stage Flotation

To protect the graphite flakes from crushing, Dingbo uses a multi-stage grinding flow. Through re-grinding and re-processing, the quality of concentrates is qualified.

Gravity Separation - Flotation Combined Technology Flow

For graphite ores with heavy minerals, Dingbo gravity separation - flotation combined technology flow can be used. The heavy minerals are separated through gravity separation, and the tailings are dealt with flotation.

Graphite Processing Equipment

Coarse crushing equipment for crystalline and amorphous graphite is the common jaw crusher. The middling and fine crushing equipment is a common cone crusher or hammer crusher. The grinding equipment uses the wet ball mill and the grid ball mill. The flotation equipment for graphite is the common JJF flotation cell, XCF flotation cell, and XJB flotation cell. The dewatering equipment of graphite is the common hydrocyclone or belt filter.

Flotation Reagent

In the multi-stage flotation process, the common foaming agents are No.2 oil, No.4 oil, ether alcohol, Rourke oil, etc; The collectors are kerosene, diesel, heavy oil, sulfonate, sulfate, phenols, carboxylic acids, etc.